-

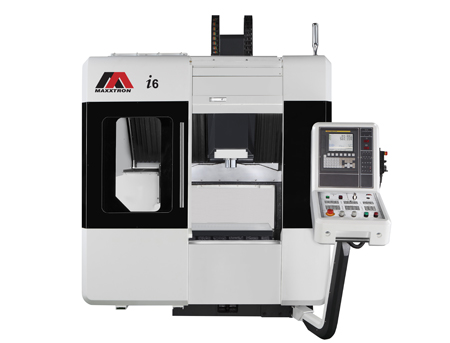

Graphite machining center

Ø All castings are Heavily Ribbed box structure design, light weight and increase structural rigidity

Ø Stepped saddle design, enhanced axial dynamic rigidity.

Ø Strong saddle and beams combination ensures superior surface, the effective increase in cutting rigidity.

Ø GANTRY structure design, three-axis movement are at the top, Linear Roller Guides, Ball screw does not accumulate dust graphite Dust perfectly suited for Mass production of graphite electrode

Ø Workbench directly fixed on the base, easy to collect dust & maintenance

Ø Grease lubrication dust-proof screw with a high coefficient rate for LM Guides.

Ø Fully enclosed sheet metal guarding highly effective graphite dust protection for Man & Machine.

Ø Oversized rear side vacuum port for effective dust suction

Ø Base slope design, graphite directly into the dust bag reduce the accumulation of graphite

Ø Base vacuum port for easy cleaning

Ø μ-class dust collection equipment, effectively filter dust Stone dust (optional)

Ø Axis Rotary table (optional)

|

Travel |

Unit |

Specification |

|

X axis travel |

mm |

600(opt:700) |

|

Y axis travel |

mm |

500 |

|

Z axis travel |

mm |

400 |

|

Dist. between spindle nose to table |

mm |

150~550 |

|

Distance between columns |

mm |

1100 |

|

Table |

||

|

Dimension |

mm |

800x500 |

|

Max Load |

kg |

500 |

|

T-slot( Width*Pitch*Number) |

mm |

5x14HxP100 |

|

Spindle |

||

|

Type |

|

Direct drive |

|

Max. spindle speed |

rpm |

12000/20000 |

|

Spindle motor power(cont. /30 min rated) |

kW |

2.2/3.7 |

|

Spindle taper |

|

BBT30/HSK-50E |

|

Feedrate |

||

|

Rapid traverse rate (X/Y/Z) |

m/min |

48/48/48 (opt:60) |

|

Cutting feed rate (max) |

mm/min |

1-10000 |

|

ATC & Maganize |

||

|

ATC Type |

|

Armless |

|

Max. tools |

pcs |

3 (opt:20) |

|

Max. diameter(next empty) |

mm |

50 |

|

Max. length |

mm |

200 |

|

Max. weight |

kg |

3 |

|

Tool shank |

|

HSK-50E |

|

Space & System Requirement |

||

|

Pneumatic pressure |

Kgf/cm |

6 |

|

Electrical power consumption |

kVA |

20 |

|

Machine net weight |

kg |

5000 |

|

Max. floor space(W*L*H) |

mm |

2600x4600x3000 |

blank

*Specifications are subject to change without notice.

|

STANDARD: lFANUC 0iMD / TFT 8.4" LCD lEthernet card,USB &RS-232C Interface lFully enclosed splash guard lSpindle cooler l3 axes absolute encoder motors lATC l 3 Axis linear guide way lCoolant tank and coolant flushing system lCentralized automatic lubrication system lSpindle air blast lWorking lamp lIndication lamp lAnchor bolts, leveling blocks and bolts lTool kits lCutting air blast lOperation manuals lDust collector |

OPTIONAL ACCESSORIES: l Built-in/Direct type high speed spindle l Heidenhain Controller MITSUBISHI Controller FANUC Controller l ATC 20T magazine lLinear scales(3 axes) lTool length measurement system(Blum) lWorkpiece measurement system lAutomatic lubrication system(Grease) lAutomatic pallet changer l4th/5th rotary table lTransformer lμ class Dust collector

|

■ APPLICATION: