Overall unit with casting

Reduce the errors of manual welding, and Low deformation and High rigidity

All casting design by box-in-box

structure, light weight and increase structure rigidity.

Integrated base casting

High stability, Low deformation, High rigidity.

Double beam design

Double beam, double saddle, four linear guideway support.

Reduce structure and thermal deformation on cutting.

Double saddle design

Double saddle design, and the lengthen and widen saddle, head and beam to reduce

deformation and increase overall rigidity.

High rigidity head

Three linear guide way and one guide way, full covered with saddle.

Octagon structure and whole foundry head.

Tough and rigidity base casting

T-type structure base increase rigidity, and the strength axes design to increase rigidity and stability,

and ensure the accuracy on high speed machining.

Gantry type column and base

Column and base fixed on foundation, without loading issue and increase machining accuracy.

Double ballscrews and double servo motors

High accuracy, High reaction, High speed.

Heidenhain linear scale

3 axes with Heidenhain linear scale to increase moving accuracy and reduce machining error.

B/C axes with ring scale

Regulate swivel and tilt angle effectively.

Mechanical anti-collision device

3 axes with anti-collision device to reduce machine failure.

Axes with cooler

Regulate moving temperature any time.

Spindle cooler

Temperature control within 0.1 degree.

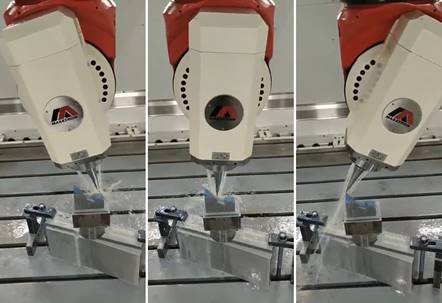

XY axes with linear motor

Rapid traverse 70 m/min, cutting feed rate 20m/min, rapid without back clearance.

Without interval gap between ballscrew and gear.

Direct-drive without other medium.

TCPM multi-axes synchronous control

Tool center management, reduce extra motion.

|

Travel |

Unit |

G2525 |

|

X axis

travel |

mm |

2500 |

|

Y axis

travel |

mm |

2500 |

|

Z axis

travel |

mm |

1100 |

|

Dist.

between spindle nose to table |

mm |

50~1150 |

|

Distance

between columns |

mm |

3320 |

|

Table |

||

|

Dimension |

mm |

2800x2800 |

|

Max Load |

kg |

5000 |

|

T-Slot |

|

14x28HxP200 |

|

Spindle |

||

|

Type |

|

Build-in |

|

Max.

spindle speed |

rpm |

24000 |

|

Spindle

motor power(cont. /S6) |

kW |

30/37 |

|

Spindle

motor torque(cont./S6) |

Nm |

72/88 |

|

Spindle

taper |

|

HSK-A63 |

|

Milling head |

||

|

Max.

swivel speed A/C |

rpm |

60/60 |

|

Max.

torque A/C |

Nm |

1030/1030 |

|

Clamping

torque A/C |

Nm |

2500/2500 |

|

Swivel

angle A/C |

degree |

±115/±220 |

|

Positioning

A/C |

arc.sec |

±3/±3 |

|

Feedrate |

||

|

Rapid

traverse rate (X/Y/Z) |

m/min |

20/20/20 opt:60/60/30 |

|

Cutting

feed rate (max) |

mm/min |

1-20000 |

|

ATC & Maganize |

||

|

ATC Type |

|

Armless |

|

Max. tools |

pcs |

30 |

|

Max.

diameter(next empty) |

mm |

100/150 |

|

Max.

length |

mm |

300 |

|

Max.

weight |

kg |

7 |

|

Tool shank |

|

HSK-A63 |

|

Space & System Requirement |

||

|

Pneumatic

pressure |

Kgf/cm |

7 |

|

Hydraulic

pressure |

kVA |

90 |

|

Electrical

power consumption |

kg |

120 |

|

Max. floor

space(W*L*H) |

mm |

8860*8260*5500 |

|

Machine

weight (no opt) |

kg |

53000 |

blank

*Specifications are subject to change without notice.

|

STANDARD: |

OPTIONAL ACCESSORIES: |

|

●HEIDENHAIN

TNC 640 5-Axis controller -15” screen and Hand

wheel -Ethernet, USB and

RS-232C interface ●3 axis

absolute encoder motors ●Euro

system Build-in Spindle 24000rpm ●2 axis

milling head & angle encoder ●HEIDENHAIN

3 axis Linear scale ●Armless

type 30 Tools magazine ●3 axis

linear guide way/P class/ roller type or same class ●3 axis

ball screw (XY with hollow cooling and surrounding supported device) ●Standard

splash guard (no roof) ●Centralized

auto lubrication system(3 axis & bearings) ●Spindle

cooler ●Spindle

air blast ●Cutting

air blast ●Cutting

coolant system ●Electric

cabinet air conditioner ●Working

lamp & Indication lamp ●Steel belt

type chip conveyor & chip cart ●Oil

skimmer ●Nitrogen

counterbalance system ●Hydraulic

system ●Coolant

flushing system ●Washing

gun & air gun ●Leveling

block and bolt & anchor ●Tool kit ●Operation

manual (electronic file |

●HEIDEHAIN/SIEMENS/FAGOR

5-Axis Controller ●KinematicsOPT/DCM ●Built-in

high speed Spindle HSK-A63/HSK-A100 ●Spindle

thermal compensation system ●2 axis

milling head ●Magazine

HSK-A63:30/60T, A100:20/40/60T ●Linear

motors-XY axis ●Centralized

auto grease lubrication system ●Tool

length measurement system ●Workpiece

measurement system ●Calibration

ball ●Casting

thermal control system ●Transformer

and regulator ●Oil mist

cutting system ●Oil mist

collector ●Scraper/Compound

type chip conveyor ●Fully

enclosed splash guard (with roof) ●CTS and

ATS |

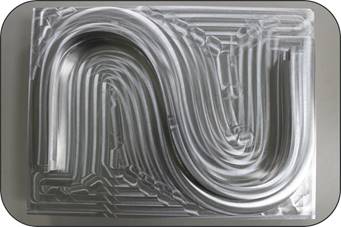

■ APPLICATION